AMECC's NEWS

TECHNOLOGY INITIATIVE, RATIONNALIZATION IN PRODUCTION, MANUFACTURING OF AUTOMATIC PIPE WELDING EQUIPMENT

TECHNOLOGY INITIATIVE, RATIONNALIZATION IN PRODUCTION, MANUFACTURING OF AUTOMATIC PIPE WELDING EQUIPMENT

|

| |||||||||

Movement initiative, rationalize manufacturing particularly important role in the use of knowledge and information to reduce costs, improve the efficiency of the competitiveness of Lisemco 2 JSC. In the past year, Officers and employees of Lisemco2 JSC has many initiatives and measures to rationalize production and application of technical advances and new technologies in order to improve productivity, product quality, improve working conditions. |

| |||||||||

The technical innovations achieved many remarkable successes, helped the workers of Lisemco 2 JSC approaches and get used to the technologies in the manufacturing business. Initiatives such as: Design and fabrication the crane systems installed in the factory, cranes installed at fabrication shop; To contribute to maintaining the environment green, clean and beautiful, protect the health of employees, the company has implemented programs designed and manufactured for the dust filtration system for manual cleaning workshop. The technical innovations, rationalize production are put into actual applications in manufacturing of entire Company.

|

| |||||||||

Typical of these initiatives has been recognized as the initiative to rationalize production of Bien Thuy Pham, Manager of Machinery control & Safety department of Lisemco 2 JSC. Initiative "DESIGN AND MANUFACTURING OF AUTOMATIC PIPE WELDING EQUIPMENT'. Automatic pipe welding equipment consists of two main parts: • Rotary rack for automatic pipe welding. • Arm welding machine 1. Rotary rack for automatic pipe welding. The set of rotating rack includes self-motivated racks and driven racks. Each rack includes 4 steel rollers, heat resistant rubber coated, with high bearing strength. A self-motivated rack has two engines of deceleration speed, is adjusted by the frequency inverter. 2. Arm welding machine. Welding machine need modern structural column with complete functions, flexible control, and convenient operation. The equipment can automatically weld with submerged arc under the flux. Welding machine includes the main column, welding arm, lifting structure, moving structure, electrical control system.

|

| |||||||||

Automatic pipe welding equipment is capable of welding circular pipe, with diameters from Ф500 to Ф3000mm, the maximum weight of 25 tons. Welding speed is stepless, the size is adjusted depending on the requirements on welding size. The equipment can execute circumferential welding and spiral welding; inside or outside pipe welding. 100% of welds were examined by UT and satisfied requirement, the weld is nice , high welding productivity. The design and manufacture of the equipment for production were saving a lot of initial investment cost compared to the purchase of foreign equipment and features. The equipment has to meet the timely progress of work "Fabrication of Cooling water supply piping system for Thai Binh coal-fired thermal power project ". With high quality weld, it has reduced weld grinding stages, reducing the cost of production (grinding, grinding stones, labor power, ...) Equipment can be engaged in the manufacture of tanks, gas tanks under intense pressure; open up prospects to field of pressure vessels fabrication. General Director of the Company has recognized the achievements of technical innovations on, by intelligence, brainpower, determination, creative dynamism, with real people, the real success on the Automatic pipe welding equipment, timely serve the production. General Director of the Company has had many forms of reward and praise promptly to all individuals, groups involved in the initiative. Promoting movement development initiatives, showing passion for this job, learning spiritual vigor, enterprising of all employees in Lisemco 2 JSC. Date: 20 Nov. 2015 By: Pham Bien Thuy

|

Tin nổi bật

-

-

Công ty cổ phần cơ khí xây dựng Amecc tham gia chương...

Ngày 22/06/2024

-

-

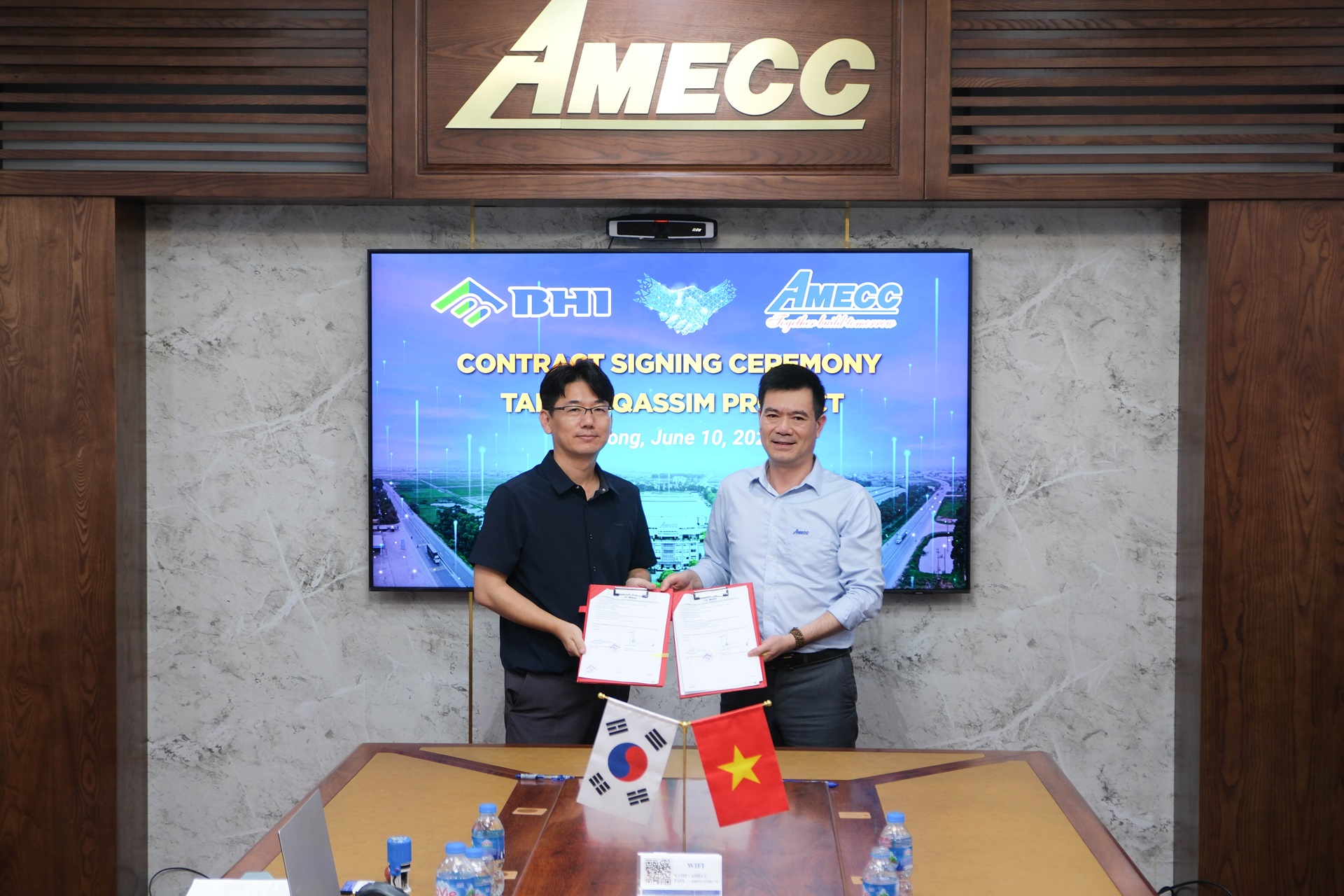

Lễ Ký Kết Hợp Đồng Cung Cấp Thiết bị HRSG Non-Pressure...

Ngày 11/06/2024

-

-

Chương Trình Đại Hội Đồng Cổ Đông Thường Niên...

Ngày 07/06/2024